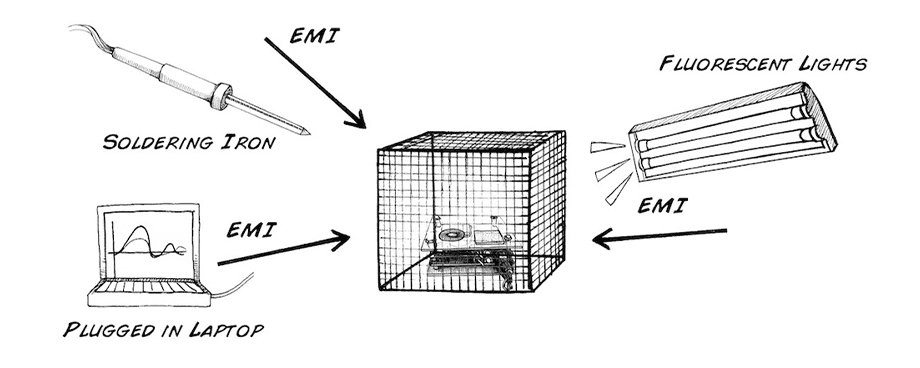

Electromagnetic wave interference not only affects the normal operation of electronic parts and components, but also does harm to human health. Using high performance EMI shielding material to isolate radiation is an effective way to protect electronic parts and components from electromagnetic interference.

Woven copper mesh

Recently, with the rapid development of 5G communication technology and chip manufacturing technology, electronic parts and components tend to be smaller, lighter, highly integrated and multi-functional, which also puts higher requirements on EMI shielding materials. Many universities also carry out related study to further improve the shielding performance of EMI shielding materials and advance the development of electronics industry.

Faraday cage for EMI shielding

Our R&D team has provided various EMI shielding solutions for many world-known universities since 2018, and has developed EMI shielding mesh that meets our customers' requirements.

Traditional metal shielding materials are mostly metal frames, metal sheets and metal gaskets made of copper, iron, nickel or aluminum alloy. However, the further application of the these metal materials in EMI shielding field are subject to its inherent defects, such as high density and high rigidity. In addiction, most manufacturers are lack of effective study on the shielding mechanism of complex materials. Therefore, we started from metal material selection, complex material structural design and modeling & simulation to solve the above problems. We prepared a series of lightweight, flexible metal EMI shielding complex materials, and adopted modeling & simulation means to study the shielding mechanism and minimize the interference of various frequencies used in various electronic equipment.

Through the study, it can be concluded that different materials have different influence on the improvement of the shielding efficiency. We developed materials that meet the requirements, such as blackened copper mesh and phosphor bronze mesh. Through the cooperation with universities, from ordering, design, calculation to finial product production, we have established a complete set of custom solution procedures and laid a good foundation for the cooperation and development of other projects.

Boegger is a technology-oriented company. We have passed ISO quality management certification. We sim to improve the technological competitiveness of key industries, establish an innovative R&D system and create good conditions for further development in the future. We can provide our customers with services from designing to manufacturing as well as the whole process technical support and solutions

Industrial Filtration & Separation

Architectural Decoration

Enterprise Press