The 21st century brought many economic and environmental challenges to the chemical industry. The future competitive advantage of the chemical industry will come from patented technology and technical knowledge. New high-yield and high quality processes will improve the production capacity of the chemical industry, while improving environmental impact and energy efficiency. A large part of the production process of the chemical industry involves filtration treatment. The filtering technology operates through special filter products and systems. It reduces solid content through mechanical separation, improves the purity of the product, and protect important equipment on the downstream of the filter.

In the chemical industry, sintered filter disc is an ideal filter element for filtration, washing and drying. It is made of multiple layers of metal wire mesh after special laminate pressing and vacuum sintering and is a metal filter material with high strength. The mesh opening of all layers interlocks with each other, forming an ideal filtration structure. We can conduct reasonable layout and design based on pore sizes, permeability and strength features.

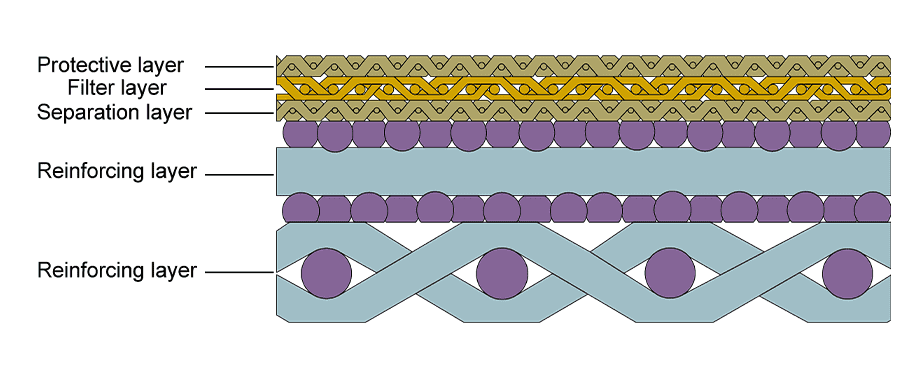

Sintered filter disc structure details

The main filter material of sintered filter disc is stainless steel sintered mesh. It generally consists of 5 layers including a protective layer, a filter layer, a separation layer and 2 reinforcing layers. The working principle of the sintered filter disc is to catch fine particles through depth filter media structure and achieve the purpose of fine particle removal.

Sintered filter disc structure

Sintered filter disc features high filter rating, corrosion resistance, good permeability, high strength, easy to clean and backwash, repeated use and reduced shutdown time. It also achieves uniform filtration under high pressure or high viscosity conditions. Our filter rating can be up to 1–200 μm.

Over the years, Boegger has been committed to providing filtration solutions for a wide range of filtration industries. With high professional production technology and product knowledge, we can provide useful suggestions on weave types, filter layers, edge types and filter ratings.

Industrial Filtration & Separation

Architectural Decoration

Enterprise Press